We’ve all been there

Almost everyone has experienced it. You step into the shower, get the  temperature just right, and within seconds it swings violently from scalding hot to ice cold. Somewhere else in the building, a tap is opened, a toilet is flushed, or another shower comes online — and your comfort disappears instantly.

temperature just right, and within seconds it swings violently from scalding hot to ice cold. Somewhere else in the building, a tap is opened, a toilet is flushed, or another shower comes online — and your comfort disappears instantly.

In domestic settings it’s an inconvenience. In multi‑user, multi‑floor buildings — hospitals, care homes, student accommodation, hotels, leisure facilities and commercial buildings — it’s a serious operational, safety and compliance issue.

And today, that long‑standing problem is being pushed to breaking point.

Changes in water conservation policy, tightening compliance expectations, and the widespread introduction of low‑flow fittings have created what can only be described as a perfect storm. Buildings that were already struggling with pressure imbalance and temperature instability are now being asked to operate reliably at lower flows, lower pressures and tighter temperature tolerances than ever before.

This blog explores why traditional shower mixers fail in these environments, why the problem is getting worse, and why a fundamentally different approach to shower design is now essential.

Why Not Listen To Our New Podcast About This on Spotify

The root cause: pressure imbalance in shared water systems

In any multi‑user building, showers rarely operate in isolation. Hot and cold  supplies are shared across risers, floors and zones, feeding dozens — sometimes hundreds — of outlets simultaneously.

supplies are shared across risers, floors and zones, feeding dozens — sometimes hundreds — of outlets simultaneously.

When demand changes anywhere on that system, pressures shift.

• A toilet flush draws cold water • A basin tap opens on another floor • A bank of showers starts up in a changing area

Each of these events alters the pressure balance between hot and cold supplies. Traditional shower mixers rely on relatively stable inlet pressures to maintain temperature. When that balance is disrupted, temperature control is lost.

The result is exactly what users experience:

• Sudden spikes in temperature • Rapid cooling when cold pressure drops • Oscillation between hot and cold • Inconsistent performance from room to room and floor to floor

In healthcare, hospitality and education environments, this is no longer acceptable — from either a safety or user‑experience perspective.

Why thermostatic mixers alone are no longer enough

Thermostatic control has long been positioned as the solution to temperature![]() instability. And while thermostatic mixers are essential, not all thermostatic mixers are equal.

instability. And while thermostatic mixers are essential, not all thermostatic mixers are equal.

Most conventional thermostatic shower valves operate with a wide temperature differential between hot and cold inlets. They rely on relatively high flow rates and stable pressures to react effectively to change.

In real‑world multi‑user buildings, those conditions rarely exist.

When inlet pressures fluctuate rapidly:

• The thermostatic element cannot respond quickly enough • The valve over‑corrects, then under‑corrects • Temperature hunting becomes inevitable

Add low‑flow operation into the mix and the problem intensifies.

At reduced flow rates, many thermostatic mixers simply fall outside their optimal operating envelope. The valve may technically remain compliant, but the user experience deteriorates — and safety margins narrow.

The low‑flow challenge: compliance meets reality

Water conservation is no longer optional.

The January 2026 UK Government White Paper on water conservation in commercial applications formally recommends the introduction of low‑flow showers and taps across non‑domestic buildings. It also outlines enforcement mechanisms, including the risk of fines and increased tariffs from water suppliers for non‑compliance.

commercial applications formally recommends the introduction of low‑flow showers and taps across non‑domestic buildings. It also outlines enforcement mechanisms, including the risk of fines and increased tariffs from water suppliers for non‑compliance.

For estates teams, designers and contractors, this creates immediate pressure:

• Lower flow rates are mandated • Existing infrastructure remains unchanged • Performance expectations stay the same — or increase

Unfortunately, most existing shower mixers were never designed to operate reliably under these conditions.

Low flow means:

• Reduced dynamic pressure • Less energy available to drive mixing • Slower thermostatic response • Increased sensitivity to system imbalance

In buildings already operating close to their hydraulic limits, low‑flow retrofits can expose serious weaknesses overnight.

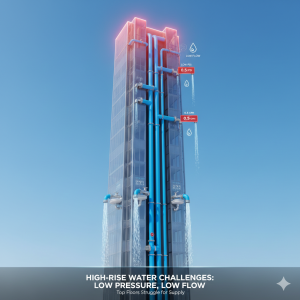

Multi‑floor buildings: where problems multiply

Pressure imbalance doesn’t just occur horizontally — it compounds vertically.

In multi‑storey buildings:

• Static pressure varies by height • Dynamic pressure fluctuates by demand • Booster sets and PRVs introduce complexity

The result is inconsistent performance:

• Top floors struggle with flow • Lower floors experience pressure surges • Temperature stability varies dramatically

Traditional mixers attempt to compensate reactively. They were never designed to proactively balance pressure across such complex systems.

The real‑world consequences

When showers fail to maintain stable temperature, the impact goes far beyond discomfort.

Safety risks

• Increased scalding risk • Thermal shock, particularly for vulnerable users • Reduced confidence in safety systems

Compliance exposure

• Failure to meet NHS and HTM expectations • Increased scrutiny from auditors • Risk of remedial works and re‑specification

Operational cost

• Call‑outs and complaints • Repeated adjustment and maintenance • Premature replacement of fittings

Reputational damage

• Poor user experience • Loss of trust in facilities • Brand impact in hospitality and healthcare

In short, temperature instability is expensive.

Why most mixers cannot meet today’s demands

The challenge facing the industry is not one of intent — it’s one of physics and  engineering.

engineering.

Most shower and tap mixers on the market today were designed for:

• Higher flow rates • Wider temperature differentials • More forgiving pressure conditions

They simply cannot operate consistently when all three of the following are required simultaneously:

- Low flow compliance

- Tight temperature control

- Highly variable pressure environments

This is why so many projects struggle at commissioning — and why so many buildings accept instability as unavoidable.

It isn’t.

A fundamentally different approach

At Challis MS, Challis Ag+ and Challis Showers, we approached the problem  from a different angle.

from a different angle.

Instead of trying to make traditional mixers cope with modern demands, we engineered a system specifically for them.

Our patented shower technology combines true pressure balancing with advanced thermostatic control, designed to operate at an exceptionally narrow temperature differential.

This combination changes everything.

Pressure balancing: stopping the problem at source

Pressure balancing ensures that fluctuations in hot or cold supply pressure are automatically compensated — before they can affect outlet temperature.

When a toilet flushes or a tap opens elsewhere in the building:

• Pressure changes are detected instantly • Hot and cold supplies are balanced mechanically • The mixing ratio remains stable

This prevents the sudden surges and drops that cause scalding or cold shock.

Unlike conventional thermostatic valves, this is not a reactive correction — it’s continuous stabilisation.

Narrow temperature differential: the hidden advantage

One of the most critical — and most misunderstood — aspects of stable shower  performance is temperature differential.

performance is temperature differential.

Our mixers operate effectively with a much narrower differential between hot and cold inlets than conventional designs.

Why does this matter?

• Faster thermostatic response • Greater stability at low flow • Reduced temperature hunting • Improved performance under pressure fluctuation

In practical terms, it means reliable performance where other mixers simply cannot cope.

Designed for low‑flow — not compromised by it

Low‑flow compliance is not an afterthought in our systems. It is engineered in from the outset.

Our showers are designed to:

• Maintain stable temperature at reduced flow rates • Operate reliably at lower dynamic pressures • Meet water conservation requirements without performance loss

This makes them ideally suited to buildings upgrading for compliance with the 2026 water conservation recommendations — without costly infrastructure upgrades.

Proven in the most demanding environments

These technologies are already in use across:

• NHS hospitals and healthcare facilities • Care homes and mental health units • Student accommodation • Leisure centres and sports facilities • Hotels and large commercial buildings

- South Pole

In these environments, performance is not theoretical — it is measured daily.

Why this matters now more than ever

The industry is approaching a tipping point.

Compliance requirements are tightening. Water is becoming more expensive. Users are less tolerant of poor performance. And systems designed for yesterday’s conditions are being pushed beyond their limits.

Attempting to solve modern problems with outdated mixer technology will only lead to:

• Increased cost • Increased risk • Increased disruption

One solution that meets every challenge

By combining:

• Patented pressure balancing • Advanced thermostatic control • Narrow temperature differential operation • Low‑flow optimisation

Our shower units are currently the only solution available that can genuinely meet and exceed the demands of modern multi‑user, multi‑floor buildings.

They remove instability from the equation — rather than trying to manage it.

Simple, safe and cost‑effective

Just as importantly, this performance is delivered without complexity.

• No specialist commissioning • No additional controls • No ongoing adjustment • No compromise on safety or comfort

For designers, contractors and estates teams, that means confidence.

Final thoughts

The days of accepting unstable showers as “just one of those things” are over.

The technology exists to deliver stable, comfortable, compliant showering — even under the most challenging conditions.

As water conservation, compliance and user expectations continue to rise, choosing the right shower technology is no longer a detail. It’s a strategic decision.

And in today’s perfect storm of pressure, flow and compliance, only one approach is truly future‑proof. Challis MS