Installing a temperature monitoring unit only confirms you may have a temperature problem — it doesn’t solve it. You’ve added cost without benefit. Real protection comes when you take action. That’s exactly what our Ag+ IoT Duty Flushing unit delivers: it closes the loop, providing the tangible solution your system actually needs.

Installing a temperature monitoring unit only confirms you may have a temperature problem — it doesn’t solve it. You’ve added cost without benefit. Real protection comes when you take action. That’s exactly what our Ag+ IoT Duty Flushing unit delivers: it closes the loop, providing the tangible solution your system actually needs.

Picture this: your building’s water systems are like a kitchen. The hot side’s the oven, the cold side’s the fridge. Now, imagine if your oven was only half-lit and your fridge letting in warm air. That would spoil dinner, right? Worse, it might even give someone food poisoning. In water systems, something similar happens if hot water isn’t hot enough, or cold water warms up too much. The result? A breeding ground for legionella and other nasty water-borne pathogens. And in places like hospitals, where patients are vulnerable, that’s simply not acceptable.

In this booklet I’ll walk through:

- What the legal, clinical, and safety guidance says about hot & cold water temperature limits

- Why keeping those temps in check matters

- What typical monitoring solutions do, and where they fall short

- How our Challis Ag+ IOT Duty Auto-Flushing Unit fills a unique gap – remote monitoring and action (flush) combined

- Real-world benefits, case study style thinking, and what you can do now

Download Your FREE Booklet Here

The Legionella Threat: The Basics

Legionella is a genus of bacteria found naturally in water. When it proliferates, particularly in man-made water systems (storage tanks, pipework, shower heads), and when aerosolised, it can cause Legionnaires’ disease – a serious lung infection. Hospitals, care homes, and other healthcare premises are especially at risk because of vulnerable people. Control of legionella is a legal duty with strong guidance underpinning it.

Legionella is a genus of bacteria found naturally in water. When it proliferates, particularly in man-made water systems (storage tanks, pipework, shower heads), and when aerosolised, it can cause Legionnaires’ disease – a serious lung infection. Hospitals, care homes, and other healthcare premises are especially at risk because of vulnerable people. Control of legionella is a legal duty with strong guidance underpinning it.

Temperature control is one of the key tools in the toolbox to prevent legionella growth. The rules are pretty clear in many jurisdictions:

- Hot water storage (calorifiers etc.) should be ≥ 60 °C. HSE+2HSE+2

- Hot water should be distributed so that at outlets, it reaches 50 °C or higher – and in healthcare settings, this often is raised to ~55 °C. HSE+

- Cold water should be kept ≤ 20 °C where possible. Once cold water warms up into the range of ~20-25 °C and above, risk of growth rises. HSE+2CDC+2

If water sits in the “danger zone” – often quoted in guidance as roughly 20-45 °C (68-113 °F) – for too long, especially in areas of stagnation (dead legs, unflushed outlets), legionella and similar microbes can multiply. CDC+

And it’s not just legionella. Other pathogens (Pseudomonas aeruginosa, for example) also benefit from warm, stagnant water. Keeping the full system in good shape is essential. The NHS’s HTM 04-01 guidance (Safe Water in Healthcare Premises) covers much of this in detail. NHS England

What the Guidance Says: What You Must Do (and Why Monitoring Matters)

The guidance from HSE, HTM 04-01, and other bodies isn’t just about putting rules on paper. It sets out steps you need to take to manage risk. Among these are:

- Design: Make sure systems are built to avoid long pipe runs, dead legs, heat

gain or loss, unnecessary storage, etc. HSE+2BEAMA+2

gain or loss, unnecessary storage, etc. HSE+2BEAMA+2 - Temperature control: Store hot water ≥ 60 °C; distribute hot water so outlets get ≥ 50-55 °C; keep cold water ≤ 20 °C. 3HSE+3HSE+3

- Flushing: Infrequently used outlets must be flushed regularly. Dead legs or pipes not in regular use are big risks. HSE+2NHS England+2

- Monitoring, inspection & maintenance: Like testing sentinel outlets’ distribution temperatures; checking the cylinder storage; inspecting cold tanks, etc. Records must be kept. HSE+2HSE+2

But here’s the rub: while guidance clearly stipulates what’s needed, doing it consistently, promptly, and with proof is often very challenging, particularly in large or complex premises.

The Challenge in Practice: Why Things Often Go Wrong

You could almost script the common problems:

- An infrequently used shower in a remote wing gets forgotten. Warmth builds up.

No one flushes, no one measures. Cue bacterial growth.

No one flushes, no one measures. Cue bacterial growth. - Thermostatic mixing valves, long pipe runs, or poor insulation lead to drop in temperature before the water reaches the outlet. Even if the storage is hot, the distal outlets are not.

- Cold water storage tanks or distribution near heat sources or adjacent to hot pipework allow cold water to warm above safe threshold.

- Manual monitoring is labour-intensive, periodic: someone checks, records, possibly misses some months. Flushing is done manually, often on schedules that may not match risk.

Also: documentation and proof are critical. If there’s an outbreak, or inspections, you need hard data showing that temperature at outlets, at sentinel points, storage, etc., has been maintained.

Adding to this, many existing monitoring systems do temperature logging or alerts, but do not take corrective action. If you detect a cold outlet has warmed, or hot water has fallen below safe threshold, somebody has to physically go and flush, or open a valve. There’s often a lag. And that lag can allow legionella to grow.

What Current Monitoring Solutions Provide – and Where They Fall Short

Lots of manufacturers and providers offer temperature sensors, logging systems, dashboards, alerts. Some offer remote monitoring, wireless sensors, etc. Quite advanced in many cases. But even so:

| Feature | Often Present | Rare or Absent |

| Hot water storage temp monitoring | ✅ | — |

| Cold water storage and main distribution temp monitoring | ✅ | — |

| Remote wireless sensors / IoT dashboards | Increasingly ✅ | — |

| Alerting when temps out of range | ✅ | — |

| Historical data & proof for compliance | ✅ | — |

| Automated action (e.g. flushing relevant section/outlet) upon an alert | ⚠️ Rarely | Usually absent |

That last column is key. Imagine your smoke alarms detecting smoke but no sprinklers, no suppression system. You get the warning, but the damage may already have begun. The same with legionella risk: detection is good; but detection + action is far better.

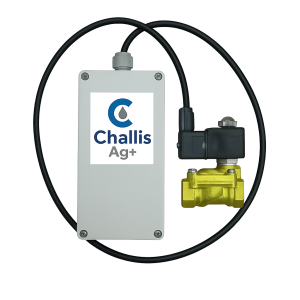

Enter the Challis Ag+ IOT Duty Auto-Flushing Unit: What We’ve Built

This is where our unique solution comes in. Let me introduce the Challis Ag+  IOT Duty Auto-Flushing Unit. (Yes, I’m biased. But sometimes being biased helps when you’ve built something that solves problems everyone has been wrestling with.)

IOT Duty Auto-Flushing Unit. (Yes, I’m biased. But sometimes being biased helps when you’ve built something that solves problems everyone has been wrestling with.)

What it does

From what I understand / what is presented on the product page:

- It monitors water temperature, both hot and cold, via connected sensors.

- It’s IoT-enabled: wireless/remote monitoring, logging of data, and alerts when temperatures drift outside safe thresholds.

- Critically, it includes auto-flushing capability. That is, when an outlet or section is identified as being stagnant or outside temperature threshold (hot too low, cold too high), the system can initiate a flush automatically to bring water through, thereby restoring safe conditions.

- It maintains records of both the temperature data and the flushing actions taken. So you have proof of action, not just proof of detection.

Why that is special

Because when you combine sensor + remote data + action, and all documented, you do more than comply. You reduce risk proactively. You reduce reliance on human checking or manual flushing schedules. You reduce lag between problem detection and correction. All of that is massively valuable in a setting like NHS Trust hospital water systems.

Scientific / Regulatory Backing: What the Research & Guidance Supports

To validate this all isn’t just theoretical, here’s what current research & regulatory guidance supports (or clues in):

- The HSE and HTM 04-01 clearly require that hot water supply be stored ≥ 60 °C, distributed so that it reaches ~50-55 °C at outlet, and cold water at or below ~20 °C. HSE+2NHS England+2

- Studies of IoT-based water quality systems emphasise parameters like temperature, turbidity, pH etc., in real-time monitoring; but largely these are monitoring only, not linking directly to corrective plumbing actions or auto‐flush mechanisms. PMC+1

- “IoT-based real-time water quality monitoring system” (Forhad et al., 2024) presents IoT systems for water quality, but the action side (flushing) is not part of typical system. PMC

- The Corporate Health & Safety Units guidance (e.g. HSG19 drafts etc.) emphasise the risk posed by water temperatures in the 20-45 °C range, and how stagnation, infrequently used outlets, dead legs, etc., increase risk.

Humorous Comparison: Temperature Monitoring Without Action Is Like…

To lighten things up (but only a bit — because this is serious), here are a few analogies:

- Like having a burglar alarm that detects a break-in but no one calls the police or locks the door.

- Like owning a car that tells you the tyre pressure is low, but no spare or inflator — you just see a warning light and hope for the best.

- Like a smoke alarm in a house with sprinklers disabled; you hear the alarm, but the fire spreads while you search for a bucket.

Challis Ag+ IOT Duty Auto-Flushing is like having both the alarm and an auto-sprinkler system. The moment things go off-range, you get notification and correction.

Benefits in Practical Terms: What You Get If You Use This Kind of System

Let’s talk in terms of benefits — what this gives you, not just what it sounds like:

- Improved safety for patients, staff and visitors

Keeping water at safe temperature ranges means less risk of legionella proliferation, less chance of infection, especially in healthcare.

proliferation, less chance of infection, especially in healthcare. - Regulatory compliance with evidence

HSE, HTM 04-01 etc expect you to monitor, document, act. Dashboards + logs + auto-flush actions = high quality proof. Useful for inspections, audits, any incident investigations. - Operational savings

Labour saved: less manual checking, less manual flushing, fewer surprise remedial works. Reduced risk can mean fewer closures or temporary interruptions. - Reduced risk and liability

If something goes wrong, having proof you had a system in place which both monitored and took action is a strong position from liability / insurance angle. - Consistent water quality & user satisfaction

Hot water that’s always hot enough, cold water always cool, users (patients, staff) don’t complain. Far less chance of scald risk or cold water being tepid in summer. - Data insights & proactive maintenance

Over time, because you’ll have temperature trends + flush logs, you’ll learn where problem spots are (e.g. certain outlets, certain wings, certain times of year). Allows you to anticipate issues (e.g. insulation problems, pipework design issues) rather than always reacting.

Potential Objections & How We Can Address Them

I’m not naïve — I know people will think of possible downsides. Let’s lay them out and respond.

| Objection | What people worry | How this kind of system (Challis Ag+) handles or mitigates it |

| Cost / upfront investment | “Sensors, IoT infrastructure, auto flush units cost more than just manual checks” | Yes, there is upfront cost — but when you factor in savings from fewer periodic interventions, lower risk of outbreak, lower legal risk, lower water waste, repair, etc., payback tends to be strong. Also, parts of this can often be phased in, or targeted to higher-risk outlets first. |

| Reliability / maintenance of equipment | “Sensors fail, flush unit stuck, false alerts” | Good systems use sensor redundancy, regular calibration, self-checking, remote diagnostics. The auto-flush focuses only where needed and logs everything (so failures are visible). Also, high quality OEM components (as in Challis system) mitigate risk. |

| Water waste / environmental concerns | “Automatic flushing will waste water” | This is a valid concern. But auto-flush systems can be tuned: only flush when needed, for minimal time; schedule etc. Also, the cost (water + energy) of occasional flushes is far smaller than risk (and cost) of infection, compliance failure, outbreak. Also, modern units monitor and record usage so you can see water usage, optimise flush durations. |

| Complexity / staff buy-in | “People prefer simpler systems, humans are used to monthly readings etc.” | Change management helps. A system that makes life easier (alerts, action, less manual work) tends to get adopted well. Also, having reliable, hard data helps buying decisions. And as staff see fewer risk incidents or complaints, trust grows. |

Specifics: Safe Temperature Ranges & Monitoring Points

To use these systems well, knowing what and where to measure is crucial. Some of the key points:

- Hot water storage temperature (calorifier): ≥ 60 °C.

- Hot water distribution: At outlets (sentinel outlets — furthest away and closest to the storage), ensure ≥ 50-55 °C achieved within 1 minute of opening. HSE+2HSE+2

- Return loops: In circulating systems, the returning water should also be at safe temperature margin; insulating pipework is essential.

- Cold water storage & cold mains distribution: Tanks should be sited to avoid heat gain, well insulated, water stored < 20 °C. Distribution lines should not bake in warm environments or be adjacent to hot pipework.

- Sentinel outlets: Pick far and near outlets as representative of the system. Monitor these monthly (hot) and regularly for cold. Also monitor infrequently used outlets, dead legs.

- Flushing policy:

• Weekly or more often for infrequently used outlets.

• When temperature thresholds breached.

• After maintenance or disruption.

Why Monitoring + Auto-Action Is the Next Step

Monitoring without action is detection only. Action closes the loop. Auto flushing is like having your building’s plumbing self-defend. Let me explain the difference with a scenario:

You get a temperature alert that a remote shower outlet is only at 42 °C (i.e. under the 50-degree threshold). Under a standard system, someone has to be notified, then schedule a visit, then physically go flush it. Meanwhile, that outlet remains risky. With a combined system, you get the alert and the system itself flushes that line (for a configured time) until temperature returns to safe level, and logs that action.

Thus, you shrink the window of exposure. You reduce dependency on human availability. And you turn passive monitoring into active risk control.

What Makes Challis Ag+ IOT Duty Auto-Flushing Unit Unique

Putting together everything above, here’s what (from your description / existing published information) makes the Challis Ag+ IOT Duty Auto-Flushing Unit stand out:

- Remote, wireless monitoring: temperature sensors installed; data sent to dashboards/portal so estates, water safety teams can see live status and historical trends.

- Auto flush capability built-in: the unit can trigger flushing without human intervention once unsafe conditions are detected.

- Dual function: monitors and acts, not just logs.

- Documentation & reporting: every temperature reading, every flush event is logged, creating traceable evidence for compliance / audit.

- Tailoring / thresholds: thresholds can be set per building type / risk profile. For example in hospitals you may want higher margins, more frequent sentinel checks, etc.

- Potential integration: Because it’s IoT, there’s opportunity to integrate with building management systems, maintenance schedules, alerting systems, etc.

Case Study Style Thinking: What This Could Do in a Hospital Environment

Let’s imagine a NHS hospital Trust has multiple wards, some older pipework, some new, some less frequently used shower & sink outlets (e.g. in a storage wing, outpatient areas).

Current State (hypothetical)

- The hot water storage tanks are well insulated and maintain ~62-65 °C.

- But at the furthest showers in one wing, hot water only gets to ~48-50 °C after 1 minute — borderline in non-critical areas, unacceptable in something like ICU or surgical wards.

- Cold water tanks in the attic space occasionally warm up in summer to over 22-23 °C, especially near warm loft spaces.

- There is a flushing schedule: weekly for many outlets, but some “forgotten” sinks / showers are flushed irregularly.

- Temperature monitoring is manual monthly checks of storage, sentinel points, some outlet checks. The rest done by spot-checks.

What using Challis Ag+ IOT Duty Auto-Flushing would bring

- Sensors in storage, at distant outlets, on cold tank, etc., feed real-time data. When one outlet’s hot water drops below, say, 50-55 °C, an automatic flush brings it up.

- Cold water that creeps above 20 °C is flushed to get fresh colder water (if from mains or circulated line).

- Records show exactly when and how often flushes occur, making compliance easy to demonstrate.

- Identifies problem spots: e.g. a shower not reaching hot temp because pipe insulation is failing, or pipe run is too long, or a mixing valve has drifted. These can be addressed proactively.

- Perhaps, over a year, fewer legionella‐related alerts / risks, fewer required remedial shutdowns, fewer complaints, and reduced risk exposure.

Potential Impact: Safety, Compliance & Cost

Let’s consider metrics and what one might expect.

| Metric | Possible Improvement |

| Number of non-compliant outlet temperatures | greatly reduced; close to zero for sentinel outlets (hot ≥ 50-55 °C, cold ≤ 20 °C) |

| Lag time between risk detection and mitigation | from days/weeks down to perhaps minutes/hours |

| Staff time on manual inspections / flushing | reduced significantly (could free up staff hours) |

| Water wasted via unnecessary flushing | probably lowered overall once system optimised, because flushes happen only when needed, and automatically controlled |

| Risk of legionella growth / infection | significantly reduced; fewer outbreaks, fewer remedial actions |

| Audit / inspection compliance | stronger evidence base; less risk of non-compliance fines or regulatory action |

What To Do Now: Steps For Estates / Water Safety Teams

If you’re thinking this sounds good (and you should), here are some practical steps to move from “well, someday we’ll do this” to “we’ve got a robust system”:

- Risk assessment refresher

Make sure the current risk assessment properly maps outlets, identifies infrequently used ones, identifies dead legs, and includes temperature monitoring and flushing schedule. - Mapping and baseline temp checks

Do a walk through: map all hot water storage, distribution, cold storage, identify sentinel outlets. Measure current hot/ cold temps, especially furthest outlets. Identify problem areas (most distant, most delayed, most warm cold tanks). - Set threshold policies

Decide what temp thresholds you’ll use (often aligned with HSE / HTM guidance). E.g. hot water ≥ 60 °C storage; ≥ 50-55 °C at outlet; cold ≤ 20 °C. - Explore and select monitoring & flushing technology

Compare providers. Ask: do they just monitor or also flush automatically? Are dashboards easy to use? How are alerts delivered? What are maintenance / calibration requirements? - Pilot / phased implementation

Perhaps pilot the auto-flushing unit in one ward or building wing. Monitor results, adjust flush durations, sensor placements etc.

- Training & documentation

Ensure estates & facilities staff know how to respond, interpret reports, maintain the units. Set up documentation / audit logs. - Review & continuous improvement

Use the data to find hot & cold spots, pipework inefficiencies, design weaknesses. Use findings to plan remedial insulation, valve replacement, redesign of problem pipe runs.

Why Waiting Is Risky

If this all seems like “nice to have”, let me underscore why delays cost more:

- The longer an outlet stays out of temperature spec, the greater chance legionella (or other pathogens) multiply. Risk to patients, staff, visitors.

- An outbreak (or even suspicion) can force parts of a hospital to be shut, deep cleaning, treatment, investigations, legal or reputational damage. Costs can skyrocket.

- Regulatory bodies increasingly expect evidence, data, prompt action. Manual or semi-manual systems are often found wanting in inspections.

- Insurance, liability: easier to defend when you have strong proactive systems with documentation.

- The cost of retrofit or remedial action when problems are found tends to be much higher than incremental investment in smart monitoring + action systems from now.

How Our World Looks If We Use The Challis Ag+ IOT Duty Auto-Flushing System

Let’s fast-forward: Several NHS Trusts across the UK have installed the Challis units across wards and in one case

- Early one summer, cold water storage tanks in a loft space begin to rise above 20 °C. The system detects it and auto flushes, bringing in cooler water; alert is logged. No outbreak, no complaint.

- An aging wing with long pipe runs starts showing drop in hot water temp at distant showers. The system flags, those lines are flushed automatically. Maintenance team then inspects insulation or redesigns those loops.

- Documentation is automatically generated monthly / quarterly with dashboard print-outs showing compliance at all sentinel outlets. In audit, this is strong.

- Estates team sees that a certain wing always needs flushes at noon (ambient heat high). They may decide to improve insulation or adjust schedule.

In short: fewer surprises, more peace of mind, safer water, happier patients and staff, better regulatory standing.

Possible Challenges & Mitigations (Real-World Practicalities)

Of course, there are always things that need careful thought. Here are some and how to plan:

- Connectivity: IoT sensors need reliable connectivity (WiFi, LoRa, etc.), power, protection. In old hospital wings, that can be tricky. Mitigation: use wired backup where possible, choose sensors with battery backup, ensure signal strength.

- Sensor calibration & reliability: Sensors drift over time; flush valves may become blocked or stick. Mitigation: maintenance schedule; self-checks; spare parts; fallback manual flushing policy.

- User behaviour: Even with auto systems, human behaviour (e.g. closing valves, adjusting TMVs, misuse) can impact performance. Mitigation: training; regular checks.

- Scald risk: Some safety rules require that mixed water delivered to users at taps doesn’t exceed safe temperatures (for preventing burns). So system must balance legionella risk vs scald risk; TMVs are still used near outlets. Documentation & design must reflect this. HSE+2HSE+2

Why This Combination (Monitoring + Auto-Flush) Is Rare But Needed

We looked earlier and saw many monitoring systems. We saw many dashboards, alerts, remote sensors etc. But the addition of automated action (flushing) when unsafe conditions are detected is not common.

Why is that?

- Because plumbing & mechanical actuation is more complex than just monitoring. You need reliable automated valves, safe power supplies, water pressure, plumbing configuration, valves that open/close reliably.

- Because of concerns about water waste and unintended consequences. Automatic flushing requires careful design.

- Because many organisations are risk averse and prefer human-in-the-loop: they want someone to decide “yes, flush now.”

But with modern IoT, better valves, better sensors, remote diagnostics, the technology is now mature enough that combining the two is feasible, safe and cost-effective. That’s what Challis Ag+ IOT Duty Auto-Flushing aims to do.

Evidence & Research That Supports The Design

Some of the most recent research highlights include:

- Forhad et al. (2024): built an IoT-based real-time water quality monitoring system; emphasised temperature among monitored parameters. PMC

- MDPI survey of IoT smart water quality monitoring systems (Jan et al. 2021): review of sensors/systems; insights into what is strong / weak. MDPI

- Studies of modular IoT systems for real-time quantitative & qualitative measurement (e.g. Syrmos et al. 2023) that explore what could be done for city water supplies. MDPI

These show interest, feasibility, technical components exist. What’s less seen (in published literature) is systems deployed in healthcare premises that combine monitoring and automatic flushing, with documented proof, under the standards needed (HTM, HSE etc.).

Conclusion: Why This Matters, Why It’s Time to Act, and Why Challis Ag+ Might Be Your Best Bet

Here are the takeaway points:

- Maintaining hot/cold water temperatures within safe limits is essential to prevent legionella and other pathogens. The legal & regulatory environment expects this, especially in healthcare premises.

- Monitoring alone is not enough: detection must lead to action. The faster unsafe conditions are corrected, the lower the risk.

- Existing solutions do much of the monitoring. The missing link is widespread, reliable auto-flush (and documentation) triggered by out-of-range conditions.

- The Challis Ag+ IOT Duty Auto-Flushing Unit offers exactly that: remote wireless monitoring + action + recording. It bridges the gap many organisations currently have.

If you are responsible for water safety this offers an opportunity: to move from reactive to proactive, to close the gaps in your system, to reduce risk, to improve compliance, to demonstrate you are using modern, best-practice tech to protect patients, staff and visitors.

Action Points: What You Can Do

If you’re reading this thinking “this is what we need”, here are some concrete next steps you might take:

- Arrange a systems audit — map all hot & cold outlets, dead legs, cold tank location, mixing valves, etc.

- Measure baseline — get current readings at storage, at sentinel outlets, cold tank, etc. See how many are out of spec.

- Explore procuring a monitoring + Challis Ag+auto flush system

- Pilot in a high-risk area – perhaps a ward, outpatient area, less used wings. Assess costs, benefits, staff response.

- Secure stakeholder buy-in – show safety benefits, compliance benefits, cost of non-compliance; possibly present this blog / summary to board, water safety group.

- Monitor & iterate – once installed, use the data. Watch for patterns. Make physical fixes (insulation, redesign, pipe shortening) where needed.

This document is based on knowledge and legislation available at the time of publication and is meant for general purposes, not for reliance on in relation to specific technical or legal issues. You should always seek independent advice. No responsibility of any kind for any injury, death, loss, damage or delay however caused, resulting from the use of the advice and recommendations contained herein, is accepted by the authors or others involved in its publication

For more information about Challis Ag+ IOT Duty Flushing Unit

Call: 01628 529024 or

email: chris@challisms.com or